Knowledgebase

*NEW* Ensuring Accurate Current Carrying Capacity for H07 Cables

Introduction

How can we determine the correct current carrying capacity (It) for H07 cables, given that there are no standardised tabulated values for these cables within ducts and ground installations? This question highlights a critical issue in electrical design and safety, as accurate values are essential for ensuring the safe and reliable operation of electrical systems.

This article aims to address this issue by discussing the general principles of practical application and verification, examining the factors that affect derating and potential discrepancies, reviewing the relevant British Standards and IEC Standards and emphasizing the importance of using manufacturer-specific data.

Practical Application and Verification

When designing electrical installations involving H07 cables, it is essential to start with a thorough understanding of practical application and verification. Generic values for It are often derived from various tables and guidelines, but these values may not fully account for specific installation conditions or cable types.

Verification of the It should always involve cross-referencing multiple data sources. While standards like BS 7671:2018+A2:2022 provide useful guidelines, they are not exhaustive. It is imperative to consult detailed manufacturer-specific data to ensure the It values are accurate for the specific cables and installation conditions in question.

Derating factors play a critical role in determining the It of cables installed in ducts or ground. These factors include soil thermal resistivity, cable depth, ambient temperature, and grouping of cables. Each of these conditions can significantly impact the It, necessitating careful consideration during the design phase.

Discrepancies can arise because different manufacturers may apply varying derating factors. Some manufacturers might reference outdated tables from BS 7671:2018+A2:2022 or other standards, such as those for 85-degree cables, which have been removed or updated in current standards. Therefore, it is crucial to verify the manufacturer-specific data to ensure compliance with design requirements.

British Standards and IEC Standards

BS 7671:2018+A2:2022 offers general guidelines for determining through tables. These tables provide a starting point by considering factors such as cable type, installation method, and ambient temperature.

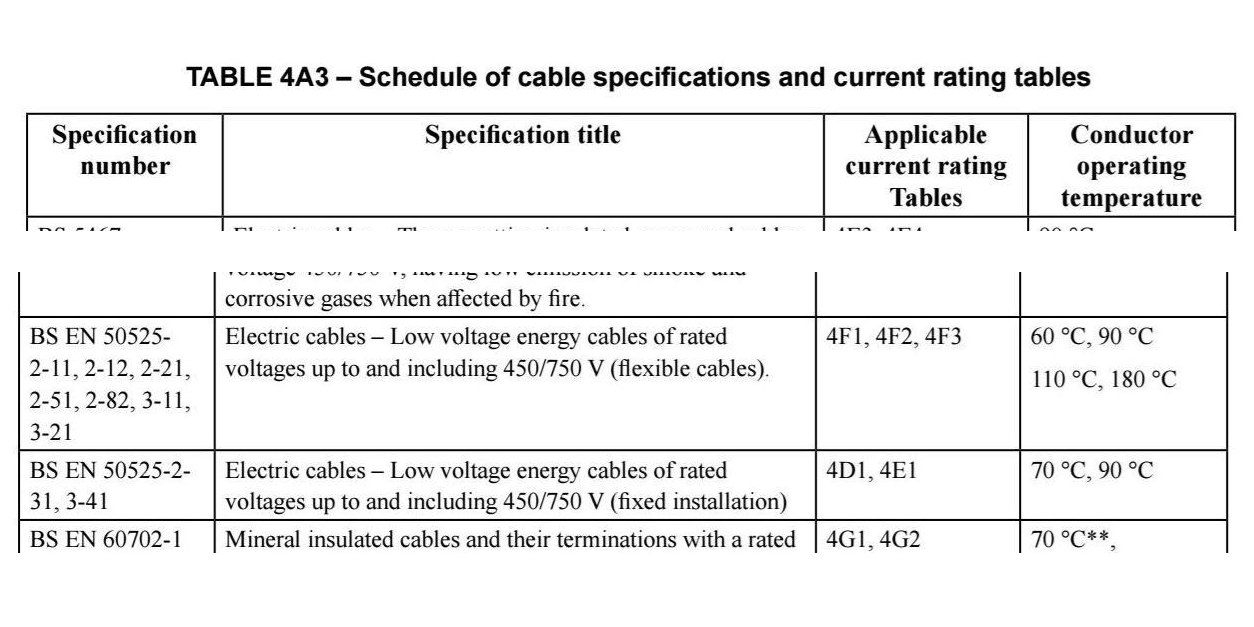

Starting at Table 4A3 we can look up BS EN 50525 series of cables. This is the standard for H0 cables such as H03, H05 & H07. Depending on what part of the BS EN 50525 series the cable you intend to use is constructed to, the cable will be classified as flexible cables or fixed installation. This distinction will determine which tables we can use.

For example;

-

A H07 cable to BS EN 50525-2-11 will be flexible and depending on the conductor operating temperature you can refer to table 4F1, 4F2 or 4F3.

-

A H07 cable to BS EN 50525-2-31 will be fixed installation and depending on the conductor operating temperature you can refer to table 4D1 or 4E1.

You should note that BS EN 50525 series of cables that fall under flexible cables, in BS 7671:2018+A2:2022 tables have no in-ground/duct data.

Additionally, now adjustments are made according to the relevant Class of the conductor. For Class 1 and Class 2 usage classifications, no correction factors need be applied. For Class 5 however, the It must be corrected as outlined in Appendix 4, Section 2.4 of BS 7671:2018+A2:2022.

-

For cables 16mm2 or less a factor of 0.95 is applied

-

For cables 25mm2 or greater a factor of 0.97 is applied

For more specific scenarios, especially involving ground installations and cable sizes greater than those in BS 7671:2018+A2:2022, IEC 60364-5-52 is invaluable. This standard, particularly tables B.52.3 & B.52.5, provides detailed data for XLPE (cross-linked polyethylene) or EPR (ethylene propylene rubber) insulated cables. This table is especially useful as it contains the necessary information for determining scenarios where no other data is available, ensuring a worst-case scenario calculation.

IEC 60364-5-52 Appendix D gives us a formula to express the current capacity of a cable of differing cross-sectional areas from a curve where conductor sizes are not provided within the tables.

As before you will still need to correct the It where relevant for Class 5 conductors

In any case, however, using the data above, be sure to specify when designating to what part what part of the BS EN 50525 series the cable must conform to. Variation of It will be hugely affected by this.

BS 7671:2018+A2:2022 regulation 522.8.10 also restricts the installation of BS EN 50525 series cables. These cables have no earthed armour or metallic sheath. So must be protected by a conduit or duct when buried in the ground by the regulation.

ERA Report No. 69-30

For determining the It of PVC and XLPE insulated cables, ERA report no. 69-30 is another useful reference. The report is referenced in BS 7671:2018+A2:2022Appendix 4 section 7 and provides sustained current ratings for various types of cables, ensuring that the It values reflect realistic performance under standard conditions.

The ERA report no. 69-30 is divided into several parts;

-

Part III focuses on sustained current ratings for PVC insulated cables, providing comprehensive data derived from extensive testing and analysis, ensuring that the It values for PVC cables are accurate and reliable.

-

Part V addresses current ratings for XLPE insulated cables, derived from the latest issue of ERA report no. 69-30 part V, which bases its calculations on BS EN (IEC) 60287. This ensures that the It values for XLPE cables are grounded in the most up-to-date standards and methodologies.

By referencing these parts of ERA report no. 69-30, designers can ensure that the It values for both PVC and XLPE insulated cables are based on rigorous testing and standard calculations, providing a robust foundation for electrical system design.

Using BS EN (IEC) 60287 for Detailed Calculations

Another valuable resource for calculating the It of cables is BS EN (IEC) 60287. This standard provides a comprehensive method for calculating the current rating of electric cables under continuous load conditions, considering electrical losses, thermal resistivity of the soil, and ambient temperature conditions.

BS EN (IEC) 60287 is particularly beneficial for complex installations where standard tables may not provide sufficient accuracy. However, applying BS EN (IEC) 60287 requires specific knowledge of the cable construction you plan to use. Detailed information about the cable, such as conductor material, insulation type, jacket material, and physical dimensions, is necessary to perform accurate calculations. This level of detail allows for precise customization of the It values to match the exact specifications and conditions of the cable installation.

Manufacturer-Specific Data

Despite the guidelines provided by BS 7671:2018+A2:2022 and IEC standards, the most accurate and reliable source of It values comes from manufacturer-specific data. Different manufacturers offer detailed data sheets for H07, H07RN, and H07ZZ cables, outlining the It and relevant derating factors based on specific installation conditions. These data sheets are crucial because they account for variations in cable construction, insulation materials, and temperature ratings. For instance, H07RN-F cables, designed for heavy-duty industrial use, and H07ZZ-F cables, which offer enhanced resistance to chemicals and oils, will have different It values and derating factors.

Conclusion

Determining the accurate It for H07 cables in ducts requires a comprehensive approach that integrates multiple data sources.

While standards like BS 7671:2018+A2:2022 and IEC 60364-5-52 provide valuable guidelines, the most critical step is referencing manufacturer-specific data. Additionally, BS EN (IEC) 60287 offers detailed calculation methods for complex installations, provided that specific knowledge of cable construction is available.

ERA report no. 69-30, referenced in BS 7671:2018+A2:2022, offers sustained current ratings for PVC and XLPE insulated cables, ensuring realistic performance under standard conditions.

By prioritizing manufacturer-specific data for detailed calculations, designers and engineers can make informed decisions that ensure safety and compliance in electrical installations.

If BS 7671:2018+A2:2022 and IEC 60364-5-52 have initially been used for the calculations. Once a specific manufacturer has been selected cable calculations should be re-run with manufacturer-specific data. Always verify cable data from manufacturers, as this is crucial for addressing discrepancies and maintaining the integrity of electrical systems.

Also Read

-

Selectivity Study (Views: 13589)

-

Max Zs Calculation (Views: 47053)

-

Schneider NSX ComPact vs ComPacT circuit breakers (Views: 1559)

-

Cables Buried and/or Ducted Current Carrying Capacities - The rating differences between BS7671 and the ERA in ElectricalOM (Views: 17571)

-

Exploring PD CLC/TR 50480:2011 and the UK National Annex NA: Additional Earth Conductors and Steel Armour in Parallel (Views: 1333)